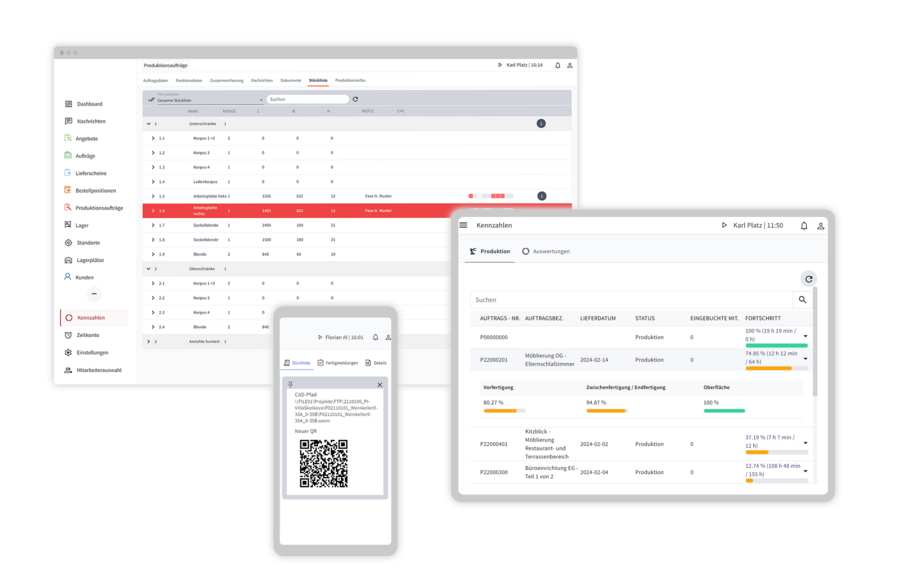

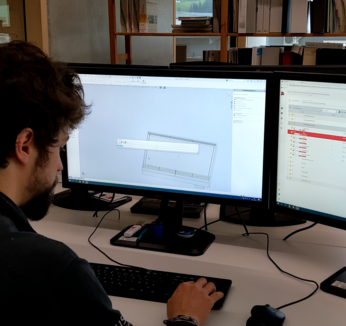

Paperless production support through a Manufacturing Execution System (MES).

Compile your orders for production orders and transmit all production data directly to your production systems. Feedback from your machines, storage systems and production staff can then be imported into Zentro and used to monitor production progress.

Zentro provides production data for your production systems via CAM interfaces and uses machine data feedback (MDC) for material requirements planning and progress monitoring. The feedback from machine data acquisition and production data acquisition is seamlessly integrated and utilised in Zentro. Digital work instructions, the option to report completion and to store notes and documents are available so that your production employees can be optimally supported in their work. These guarantee a smooth process and help to minimise errors.

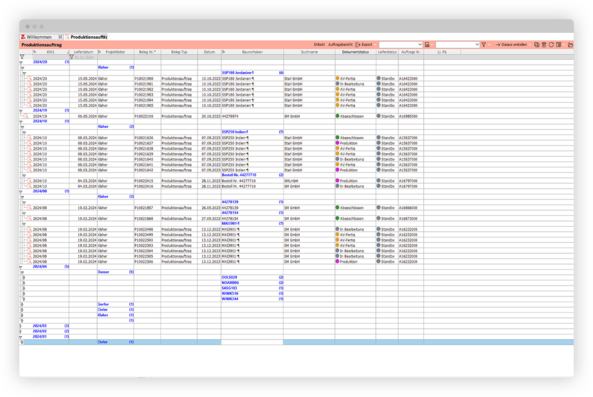

Planning and processing of production batches.

- Compilation of production orders from the orders placed and direct transmission to the production facilities.

- Connection of organisational objects in connection with service accounting (e.g. buildings, rooms, plant components).

- Management of production parts lists.

- Batch planning, both order-dividing and cross-order: splitting or summarising orders into production batches.

Manufacturing Execution System (MES) with integration into the company process.

- Creation of production order-related purchase orders with cross-reference to the original order.

- Process automation through machine interfaces, production data acquisition (PDA), machine data acquisition (MDA) and personnel data acquisition is possible.

- Link to Zentro capacity planning and time recording.

- Automated allocation of working time and material costs to production orders.

- Post-calculation at production order level or sales order level.

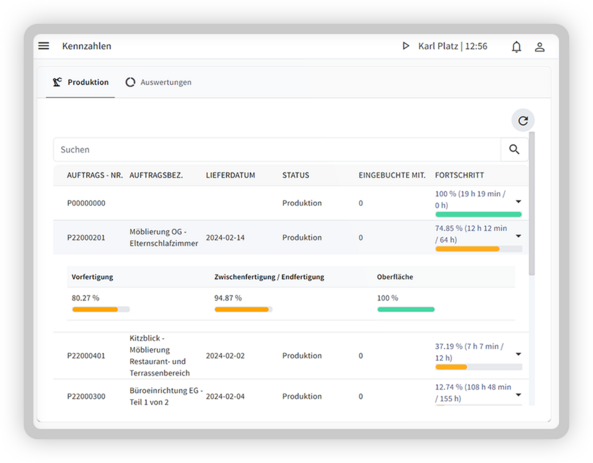

Production monitoring: mobile monitoring.

- All projects clearly organised on one screen, also via tablet and smartphone.

- Digital production progress monitoring and visualised degrees of completion.

- Basis for decision-making to improve your production processes.

- More feedback and planning reliability with less effort.

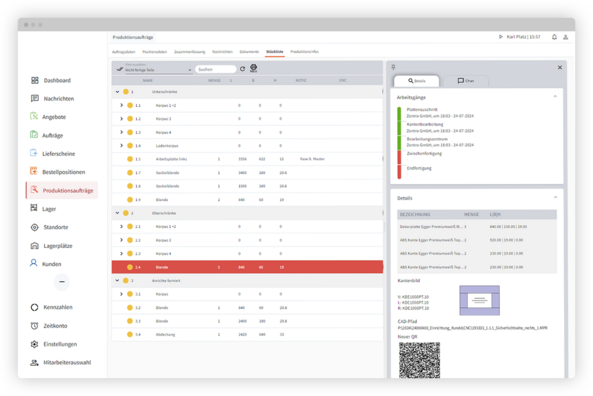

Detailed information on the

production terminal and completion notification:

- Display of material availability for purchased parts.

- Parts-based status information on the work steps completed for a component.

- Cost centre-based target time calculation as a guideline for the processing time in production.

- Progress monitoring and completion notification at product, group or individual part level.

Thanks to the digital completion report, production management knows exactly how production is progressing and can control it accordingly.

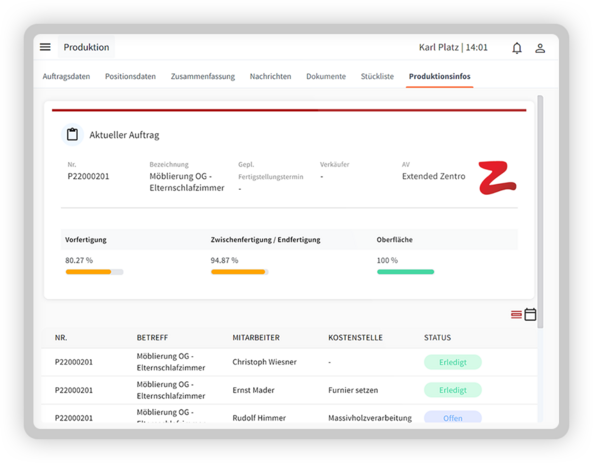

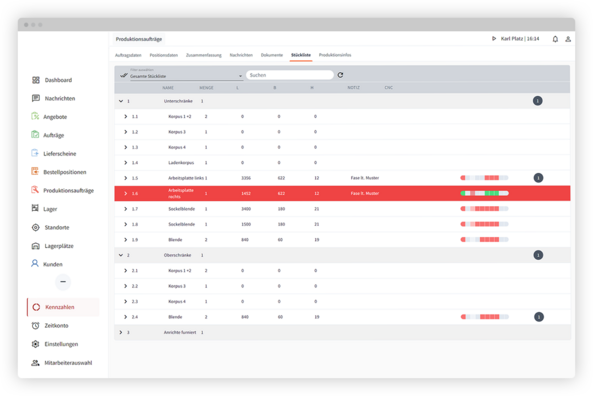

Individual part tracking:

Production feedback on a per-part basis.

Knowing exactly how production is progressing at all times, even with a batch size of 1, minimises uncertainty in planning and creates leeway in project management and customer communication.

- With individual part tracking, nothing gets lost in the hectic daily work routine.

- Feedback is structured as part-based production feedback.

- Problems can be responded to promptly.

- Missing parts can be re-produced without delay.

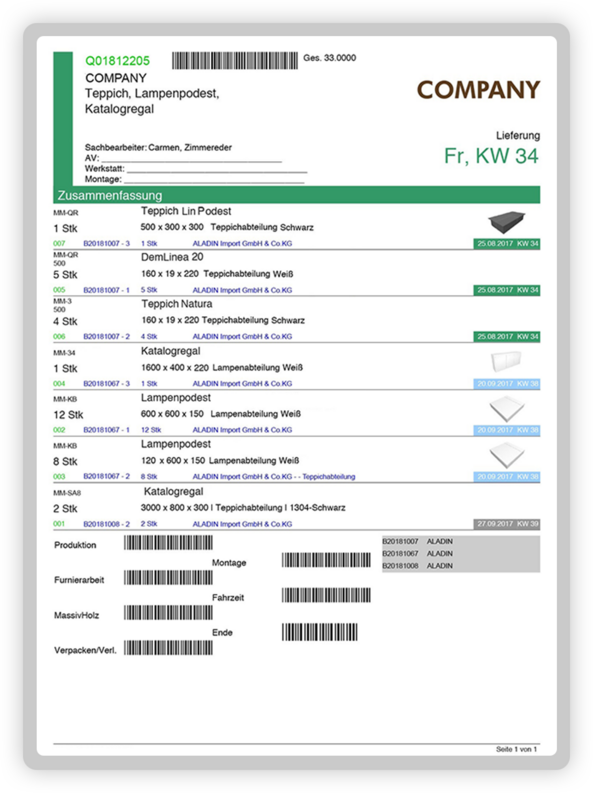

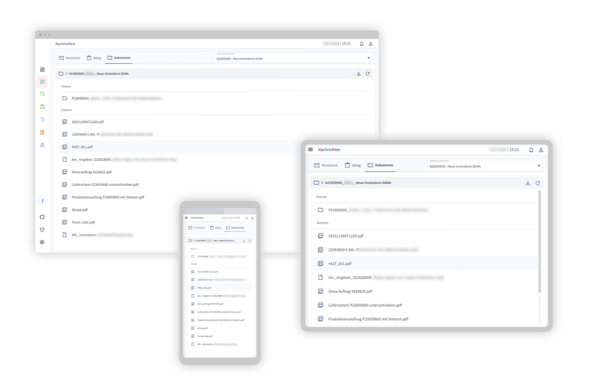

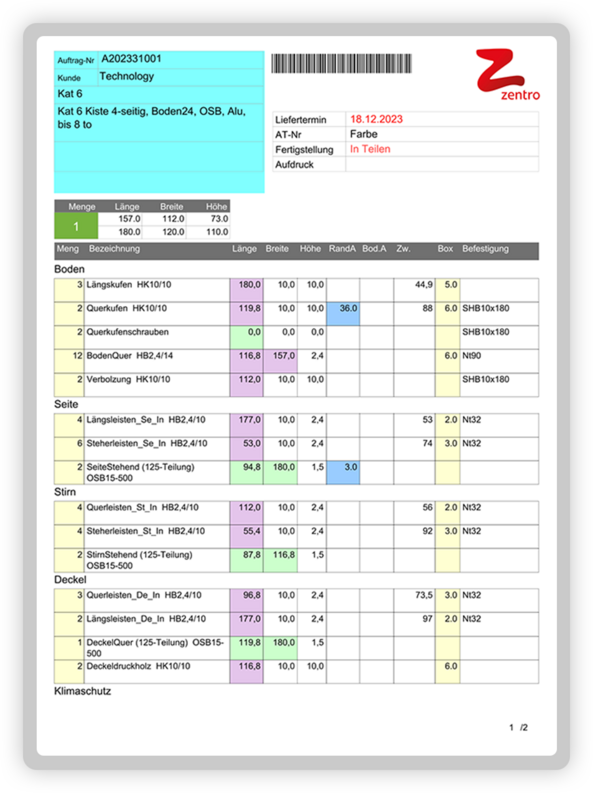

Digital production documents: Printing was yesterday!

If plans are changed, the associated parts lists and digital routing slips are automatically updated and are available to production staff in real time:

- Printing out documents becomes superfluous.

- Up-to-date digital parts lists and additional information instead of outdated paperwork.

- Mobile documents pave the way for paperless production (paperless factory).

Transparency and efficiency for all employees - No unanswered questions.

Everyone involved in the project should have access to the documents they need for their work - in the most up-to-date version:

- Parts lists, planning data, photos, supplementary production and assembly information and much more are available digitally for the project.

- Documents can also be submitted at short notice.

- Authorisation systems regulate access so that everyone can see what they are allowed to see.

- Access via terminal in production or on the move via tablet or smartphone.

Lists and pdf documents: To send and take away!

Production documents can be customised to your needs:

- Production documents: with article images and colour coding by calendar week.

- Barcodes and QR codes: Practical for scanning cost centres, orders or items.

- Workshop order papers, routing slips, packing slips and production parts lists in A4/pdf format

- ...

Our production software is available as an add-on module to our ERP variants

ERP Light | ERP Compact | ERP Extended |

|---|

| Production management | |||

| Batch planning: order splitting and cross-order planning | No | Yes | Yes |

| Division of projects into production batches/work packages | No | Yes | Yes |

| Automated allocation according to function or position hierarchy | No | Yes | Yes |

| Management of semi-finished products | No | No | Yes |

| Production BOM cancellation | No | Yes | Yes |

| Determination of material requirements and triggering of production orders | No | Yes | Yes |

| Link to project and object elements (e.g. building, room, ...) | No | No | Yes |

| Organisational element of internal work packages | No | Yes | Yes |

| Possibility to summarise items across orders | No | Yes | Yes |

| Possibility to summarise items across orders | No | Yes | Yes |

| Production lot relevant cost recording and final costing | No | Yes | Yes |

| Work package based material reservation | No | Yes | Yes |

| Production proposal (based on available stock) | No | Yes | Yes |

| Printing option for working papers and labelling | No | Yes | Yes |

| Assembly status and ready message | No | Yes | Yes |

| Production log and QM data | No | Yes | Yes |

| Document storage and linking to data sheets | No | Yes | Yes |

| Serial number generation and labelling | No | Yes | Yes |

| Production orders: internal task management for work packages/production batches | No | Yes | Yes |

| Production documents: Workshop order papers, routing slips, packing slips and production parts list in A4/pdf format | No | Yes | Yes |

| Barcodes and QR codes: Scanning of cost centres, orders or articles | No | Yes | Yes |

| Interfaces to production systems | No | Yes | Yes |

| Parts-based production control | |||

| Digital production parts list | No | No | Yes |

| Unique part ID | No | No | Yes |

| Status/ready message per operation and individual part | No | No | Yes |

| Definition of delivery units and monitoring of the degree of completion at part level | No | No | Yes |

| Definition of packages and container allocation | No | No | Yes |

| Part-related production times | No | No | Yes |

| Part-related reference/chat option with concrete typification and responsibility regulation | No | No | Yes |

| Production and quality documentation per part/assembly | No | No | Yes |

| Identical part recognition for simplified calculation of working times | No | No | Yes |

| Plan/document management for assemblies or individual parts | No | No | Yes |

| Material-related production lots | No | No | Yes |

| Alternative production routes | No | No | Yes |

Benefit from production interfaces:

- Export of production parts lists for your CAM system

- Import of machine data feedback

- Synchronisation with automated warehouse systems

- Machine data acquisition (MDE), e.g. of production quantities

- Production data acquisition (PDA), such as feedback of order-related work performance, order status

Progress feedback for production monitoring

Do you need more information on automation and interfaces?

Paperless Factory.

"We were looking for a long time for a solution that could meet our requirements in terms of innovation, flexibility, transparency and ease of use. Zentro Go was able to fulfil our individual requirements 100%."

Konrad Grömmer

Managing Director, Tischlerei Grömmer

Success stories from our customers.

CARPENTRY

"With Zentro, we finally have all the information in one place. Everyone knows exactly what the status of an order is and what's coming up next. That makes our day-to-day work much easier."

Heiko Moldaschl

Junior manager and workshop manager

Schreinerei Moldaschl

Patrick Fleig

Technical Managing Director

Schreinerei Moosmann

BUILDING and FURNITURE CARPENTERS

"Everything works at least as promised and better than we thought it would."

Franz Hackl sen.

Managing Director

Tischlerei Hackl

CARPENTRY

"The biggest advantage of Zentro for us is that all processes are mapped in one interface. This creates transparency and traceability of orders. I chose Zentro because I think it's the best programme on the market."

Rüdiger Huschle

Managing Director

Schreinerei Huschle

PROPERTY DECORATOR

"We were looking for a long time for a solution that could meet our requirements in terms of innovation, flexibility, transparency and ease of use. Zentro Go was able to fulfil our individual requirements 100%."

Konrad Grömmer

Operations manager

Tischlerei Grömmer

Do you have any questions? We will be happy to advise you.

We look forward to your call at

!

Please write to us at

by e-mail!

Zentro GmbH

Grubbachstr. 71

4644 Grünau im Almtal

Austria