3-in-1:

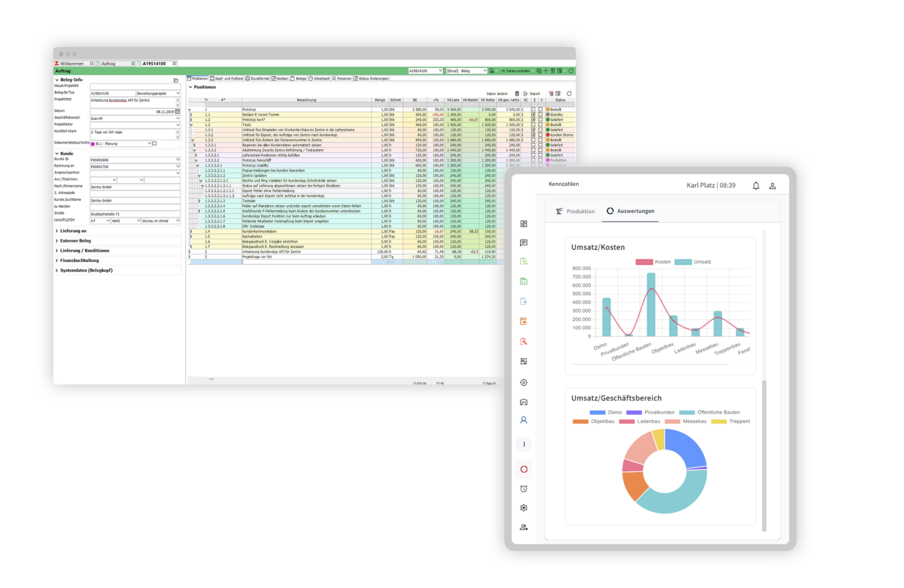

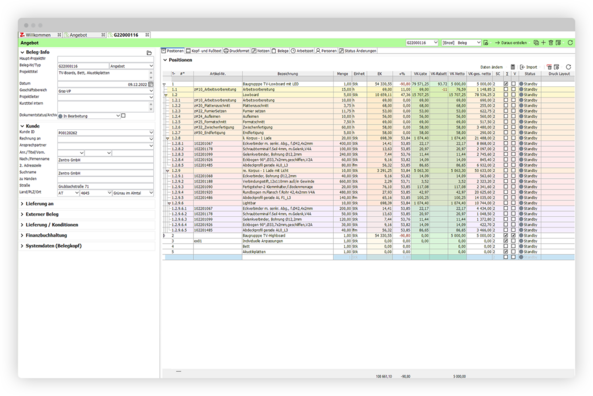

Project-related bill of materials, cost determination and completeness check.

Our costing software calculates prices and quantities on several levels, including the conversion of square metre prices and units. Metal surcharges can be efficiently recorded and managed, while discounts on items, groups or totalling items are calculated accurately.

The software supports effective filtering, sorting and structuring of line items. With integrated controlling, it automatically totals labour times and prices and calculates surcharges precisely. User-friendliness is guaranteed by functions such as spell checking, article images, dimensions and stock information as well as cross-references.

You can choose between costing in project-specific assemblies or a product configurator with a technical parts list:

Multi-level calculation

directly in the quotation document.

- Assembly costing, calculation of unit prices and quantities, agile project parts lists

- Flexibly structured costing levels, quick, detailed and variant costing per assembly with task distribution

- Measurement and checklist-based quantity determination

- Structured design options for quotation documents and costing from a single source

Network the knowledge

in your company.

- Save and use checklists, parts lists, quotation and calculation templates

- Meta levels such as objects (devices, buildings, systems, ...), work packages and business areas

- Manage contact persons, delivery addresses, serial numbers, responsibilities ... directly in the project

- Price comparison table for comparing prices across different offers and enquiries

- Record and delegate offer-related documents, notes and tasks

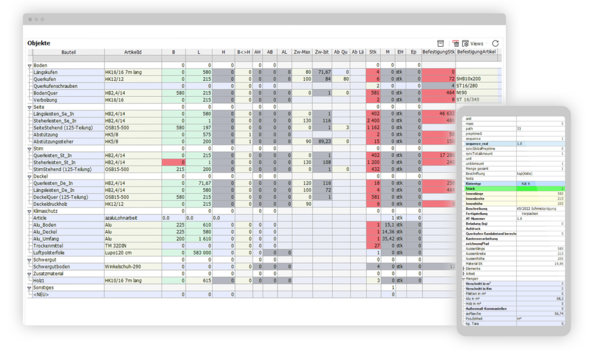

Technical parts list with determination of time and material requirements

The technical parts list is a specialised application that helps you to efficiently calculate individual solutions for your customers and to automate work preparation to a large extent. You can determine working times and costs and individually configure parameterisable quotation texts, which are then automatically inserted into the quotation. This enables a higher level of detail in the quotation and more accurate invoicing based on dimensions. The software also offers a checklist function.

Automated: From the plan, through capacity planning, to production.

- Your CAD planning data is supplemented by the software to create production-ready parts lists.

- Gain know-how: your production knowledge is formalised and distributed throughout the company.

- Generate the preliminary costing for material and labour time from your parts lists.

Product configurator

for calculation and production parts lists.

- Production parts list, cost calculation and completeness checklist in one.

- Calculation of standard times and material requirements with recognition of identical parts.

- Consideration of specific production steps based on the respective conditions in the company (machine equipment, process times).

Automated production and material planning

The product configurator enables the generation of CNC parameters and the storage of CNC macros, as well as export to machines. The automated creation of labels and production documents is also possible, which can be used either on paper or paperless.

Another useful function of the product configurator is the automated decision on whether to purchase from stock or buy in, as well as the search for the best-price supplier.

Costing in assemblies is integrated in our ERP variants...

ERP Light | ERP Compact | ERP Extended |

|---|

| Calculation in assemblies | |||

| Practical calculation structure for your project structure | Yes | Yes | Yes |

| Assembly costing | Yes | Yes | Yes |

| Agile project BOMs | Yes | Yes | Yes |

| Flexible level structure | Yes | Yes | Yes |

| Calculate unit prices | Yes | Yes | Yes |

| Automated mark-up calculation | Yes | Yes | Yes |

| Discounts for items and groups, total discount | Yes | Yes | Yes |

| Calculation checklists | Yes | Yes | Yes |

| Variant costing per assembly | Yes | Yes | Yes |

| Automated correction functions for quantities and prices | Yes | Yes | Yes |

| Cross-references to recorded data, working hours and other documents | Yes | Yes | Yes |

| Design of quotations with calculation, images and texts | Yes | Yes | Yes |

| Quotation document and calculation from a single source | Yes | Yes | Yes |

| Status tracking for your projects and project parts | Yes | Yes | Yes |

| Integrated controlling with plausibility and completeness check | Yes | Yes | Yes |

| Offer-related documents, notes and tasks | Yes | Yes | Yes |

| Calculation templates | Yes | Yes | Yes |

| Text modules for conditions and contract terms | Yes | Yes | Yes |

| Spell check | Yes | Yes | Yes |

| Price comparison table for price comparison of various offers and enquiries | No | No | Yes |

| Many import and export options (interfaces) | Yes | Yes | Yes |

The detailed technical parts list and the product configurator are available as additional modules for our ERP variants

ERP Light | ERP Compact | ERP Extended |

|---|

| Detailed technical parts list | |||

| Expert system for the simple creation of multi-level BOMs | No | Yes | Yes |

| Any complex calculation logic for materials | No | Yes | Yes |

| Any complex time calculation at component level | No | No | Yes |

| Calculation of dimensions and weights | No | Yes | Yes |

| Classification of components in predefined categories | No | Yes | Yes |

| Classification of components in any categories | No | No | Yes |

| Assemblies and component management | No | Yes | Yes |

| Any complex component parameters | No | No | Yes |

| Management of drawing number and CAD references | No | Yes | Yes |

| Management of documents for components | No | Yes | Yes |

| Cumulative assembly recording | No | Yes | Yes |

| Use of project material specifications | No | Yes | Yes |

| Flexible data structure per assembly/component | No | Yes | Yes |

| Expert system based material determination | No | Yes | Yes |

| Automated determination of work processes | No | Yes | Yes |

| Cost centre-related working time determination for materials | No | Yes | Yes |

| Cost centre-related working time determination for components | No | No | Yes |

| Digital parts list view optimised for materials | No | Yes | Yes |

| Workstation optimised digital parts list view | No | No | Yes |

| Paperless interactive production bill of materials | No | Yes | Yes |

| Assembly parts list for final assembly (incl. link to documents and detailed information) | No | Yes | Yes |

| Internal task management for work packages/production batches | No | Yes | Yes |

| Many import and export options (interfaces) | No | Yes | Yes |

| Product configurator | |||

| Input assistant for calculation and determination of requirements | No | No | Yes |

| Definition of any number of deeply nested parameter sets | No | No | Yes |

| Predefined selection options | No | No | Yes |

| Plausibility checks | No | No | Yes |

| Specification of possible combinations | No | No | Yes |

| Any complex calculations | No | No | Yes |

| Limit check and variant logic | No | No | Yes |

| Use of project parameters | No | No | Yes |

| Inheritance of object and project properties | No | No | Yes |

| Inheritance logic based on object orientation | No | No | Yes |

| Inheritance of element properties | No | No | Yes |

| High degree of reuse through inheritance logic in assembly definition | No | No | Yes |

| Automatic generation of costing and production parts lists | No | No | Yes |

| Automatic product price determination (possibly independent of material and time requirements) | No | No | Yes |

| Automatic generation of product description | No | No | Yes |

| Automatic determination of material and time requirements | No | No | Yes |

| Price calculation for product types based on predefined models | No | No | Yes |

| Pricing model based on part sizes | No | No | Yes |

| Logistics costs based on calculated weights | No | No | Yes |

| Pricing based on project-related parameters | No | No | Yes |

| MakeOrBuy: Consider external production option | No | No | Yes |

| Data preparation for external production | No | No | Yes |

| Many import and export options (interfaces) | No | No | Yes |

Benefit from

- Practical calculation structure in your project structure

- Cross-references to recorded data, working times and other documents

- Multi-level costing with flexibly reusable data

- Status tracking for your projects and project parts

- Integrated controlling with plausibility and completeness check

- Automated mark-up calculation

Seamlessly integrated.

"The biggest advantage of Zentro for us is that all processes are mapped in one interface. This creates transparency and traceability of orders."

Rüdiger Huschle

Owner and Managing Director, Schreinerei Huschle

Filtering is possible within a cost estimate and across all created cost estimates. For example, you can filter by article number, working time articles, materials, quantities, customers, descriptions, prices, etc.

Yes, the release process is mapped via status releases and the rights system. There is a document status for each document and a delivery and billing status for each document item. The characteristics of the various status values and the rights can be defined individually.

The calculation can be carried out directly in the quotation document, whereby the calculation rules are stored in a similar way to formulas in Excel.

Text templates can be mapped using the article master, whereby the creation of assemblies is also provided for. All calculation data is saved in the quotation document in the relational database.

Post-calculation offers, for example, a target/actual comparison of price and quantities per consumed or calculated item or at product group level. A report generator and various chart types (column, bar and line charts), pivot tables and heat maps are also available.

Yes, Zentro allows you to change the calculation at a later date if you wish.

Yes, thanks to the free filter and grouping options in combination with the available data sources, evaluations regarding turnover, actual cost-based contribution margins and much more can be generated as required. Comparisons by order, project, customer, salesperson, project engineer and other criteria can therefore be realized individually and without additional programming.

Yes, the final costing is an evaluation that is created automatically on the basis of the quantities and prices from the preliminary costing, the recorded working times and the materials used. Various display formats are provided. The evaluation of costs and mark-up factors can be configured variably for each product group and cost element.

In preliminary costing, the costs can be calculated with various mark-ups and mark-downs and compared with the planned sales price for each item.

The sales price of an item can optionally be totaled from the sales prices of its sub-items or freely defined. The calculation of the contribution margin is available at every level.

Yes, quantities and units (e.g. time units, pieces, units of measurement), packaging quantities and conversion factors (e.g. for different units in purchasing and sales) and much more can be taken into account.

Yes, the surcharges are provided for each costing item. Surcharges that are standardized across companies, such as metal surcharges, are managed as sub-items for better maintainability.

With the help of cost centers and freely definable evaluation dimensions, production specifics can already be defined and taken into account in the calculation or when creating articles.

Success stories from our customers.

CARPENTRY

"With Zentro, we finally have all the information in one place. Everyone knows exactly what the status of an order is and what's coming up next. That makes our day-to-day work much easier."

Heiko Moldaschl

Junior manager and workshop manager

Schreinerei Moldaschl

Patrick Fleig

Technical Managing Director

Schreinerei Moosmann

BUILDING and FURNITURE CARPENTERS

"Everything works at least as promised and better than we thought it would."

Franz Hackl sen.

Managing Director

Tischlerei Hackl

CARPENTRY

"The biggest advantage of Zentro for us is that all processes are mapped in one interface. This creates transparency and traceability of orders. I chose Zentro because I think it's the best programme on the market."

Rüdiger Huschle

Managing Director

Schreinerei Huschle

PROPERTY DECORATOR

"We were looking for a long time for a solution that could meet our requirements in terms of innovation, flexibility, transparency and ease of use. Zentro Go was able to fulfil our individual requirements 100%."

Konrad Grömmer

Operations manager

Tischlerei Grömmer

Do you have any questions? We will be happy to advise you.

We look forward to your call at

!

Please write to us at

by e-mail!

Zentro GmbH

Grubbachstr. 71

4644 Grünau im Almtal

Austria

© 2024 Zentro GmbH