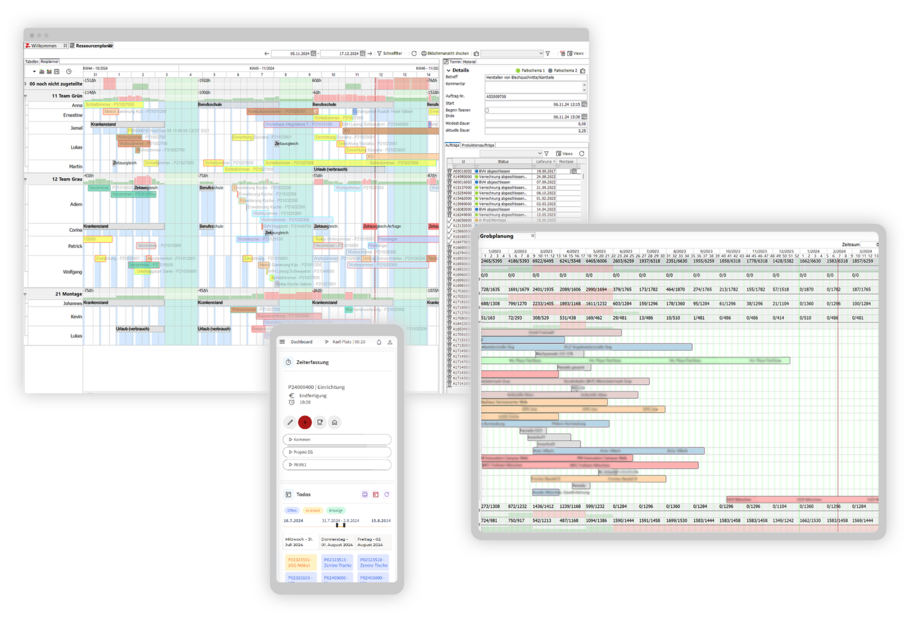

Digital planning board: Capacity planning and assembly scheduling

Optimise your capacity and assembly planning with the planning board from Zentro and get a clear overview of your projects. Our resource planning enables you to schedule your orders - whether through automated backward scheduling or intuitive manual planning using drag and drop. Zentro automatically takes into account feedback from time recording to ensure precise utilisation of your resources.

With our control centre for machine and personnel resources, you can rely on a holistic solution that makes your capacity and assembly planning efficient and transparent. Improve your capacity planning and increase your company's productivity. Find out more about how Zentro can take your projects to the next level.

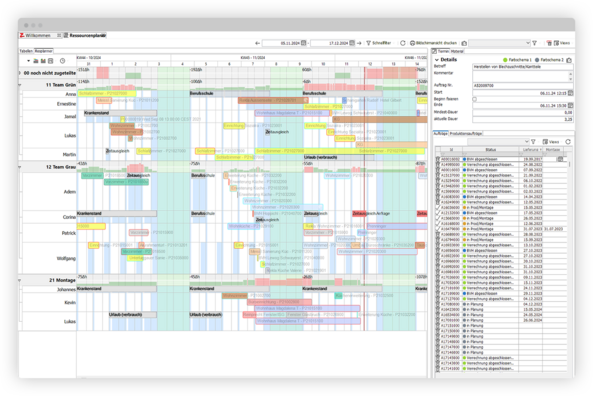

Editable bar chart for planning projects and production.

- Utilisation chart: Recognise where capacities are free or scarce

- Schedule orders via drag and drop to the appropriate date or with automated backward scheduling

- Link, fix or split appointments

- Grouping of appointments and filtering of projects

- Visual control for a practical overview of all current projects

Utilisation and detailed planning.

- Clear visualisation and optimisation of capacity utilisation for efficient project planning.

- Control centre for machine and personnel resources that links project data and deadlines.

- Integration of resource potentials, target times, delivery dates and hours worked in a user-friendly graphical tool.

- Simple overview: visualisation of status, category and order assignment using symbols, colours, fonts and frames.

The resource planning is available as an add-on module for our ERP variants

ERP Light | ERP Compact | ERP Extended |

|---|

| Planning board for machine and personnel resources | |||

| Graphical planning of deadlines for quotations, orders or production orders | Yes | Yes | Yes |

| Editable bar chart (Gantt) with multi-dimensional typing | Yes | Yes | Yes |

| Automated scheduling (from order or production order) and/or manual scheduling | Yes | Yes | Yes |

| Assignment of any number of resources per appointment | Yes | Yes | Yes |

| Assignment of status, category and other dimensions | Yes | Yes | Yes |

| Management of appointment details such as metadata and description | Yes | Yes | Yes |

| Sorting and filtering options for appointments | Yes | Yes | Yes |

| Multi-dimensional graphical representation with changeable level of detail | Yes | Yes | Yes |

| Networking to projects, merchandise management, production management and time recording | |||

| Linking of orders to be completed and production orders | Yes | Yes | Yes |

| Simplified order scheduling through display of order parts and pre-calculated quantities | Yes | Yes | Yes |

| Overview of all booked appointments in the system | Yes | Yes | Yes |

| Management of appointment details such as metadata and description | Yes | Yes | Yes |

| Order-related capacity and assembly planning directly with the order | Yes | Yes | Yes |

| Prioritisation and specification of work steps at the employee terminal | Yes | Yes | Yes |

| Real-time feedback on production progress based on time or quantity recording | Yes | Yes | Yes |

| Link to employee availability and time recording data | Yes | Yes | Yes |

| Automations | |||

| Sequence assignment of appointments | Yes | Yes | Yes |

| Retrograde scheduling of required resources | Yes | Yes | Yes |

| Automated backward scheduling of processing steps based on the delivery date and the calculated time requirement | Yes | Yes | Yes |

| Consistency checks for multi-part tasks | Yes | Yes | Yes |

| Workload visualisation and optimisation | Yes | Yes | Yes |

| Queuing, fixing, coupling and decoupling of appointments | Yes | Yes | Yes |

| Automated allocation of cost centres, productivity factors and buffer times | Yes | Yes | Yes |

| Automated monitoring of completion progress using graphical support | Yes | Yes | Yes |

| Visualisation | |||

| Integration of resource potential, target times, delivery dates and hours worked in a graphical tool | Yes | Yes | Yes |

| Display of status, category and order assignment using icons, colours, fonts and frames | Yes | Yes | Yes |

| Different levels of detail in the view (e.g. time scale, employees/groups, workload summary) | Yes | Yes | Yes |

| Visualisation of schedule conflicts using colours | Yes | Yes | Yes |

| Visualisation of completion progress using symbols | Yes | Yes | Yes |

| Visualisation of workload at resource and group level | Yes | Yes | Yes |

| Highlighting of deadlines per order | Yes | Yes | Yes |

| Visualisation of filtered appointments, e.g. by customer | Yes | Yes | Yes |

Benefit from

- Automated backward scheduling of work steps based on delivery dates and time requirements

- Integration of resource potential, target times, delivery dates and completed working times in a graphical tool

- Automated monitoring of completion progress using graphical support

- Sorting and filtering options for deadlines

- APS (Advanced Planning System) or PPS (Production Planning and Control System)

- Visualisation and optimisation of capacity utilisation

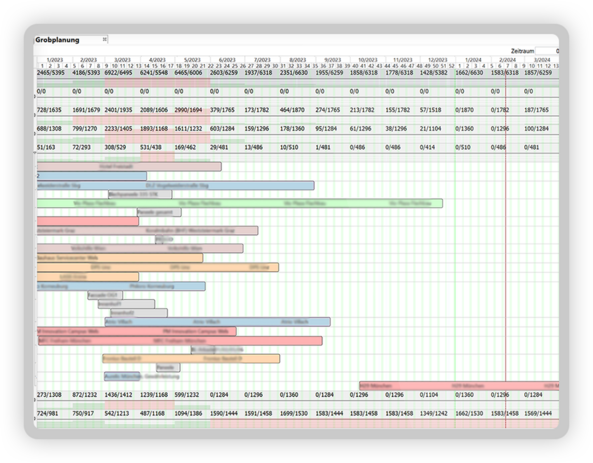

Overview of order utilisation

A good overview of order utilisation makes it possible to make important strategic decisions. For this purpose, the planned working times from the order costing are integrated directly into capacity planning and automatically distributed to individual groups, employees or machines depending on the desired level of detail. Working time data, documents and their target times or delivery dates are taken into account.

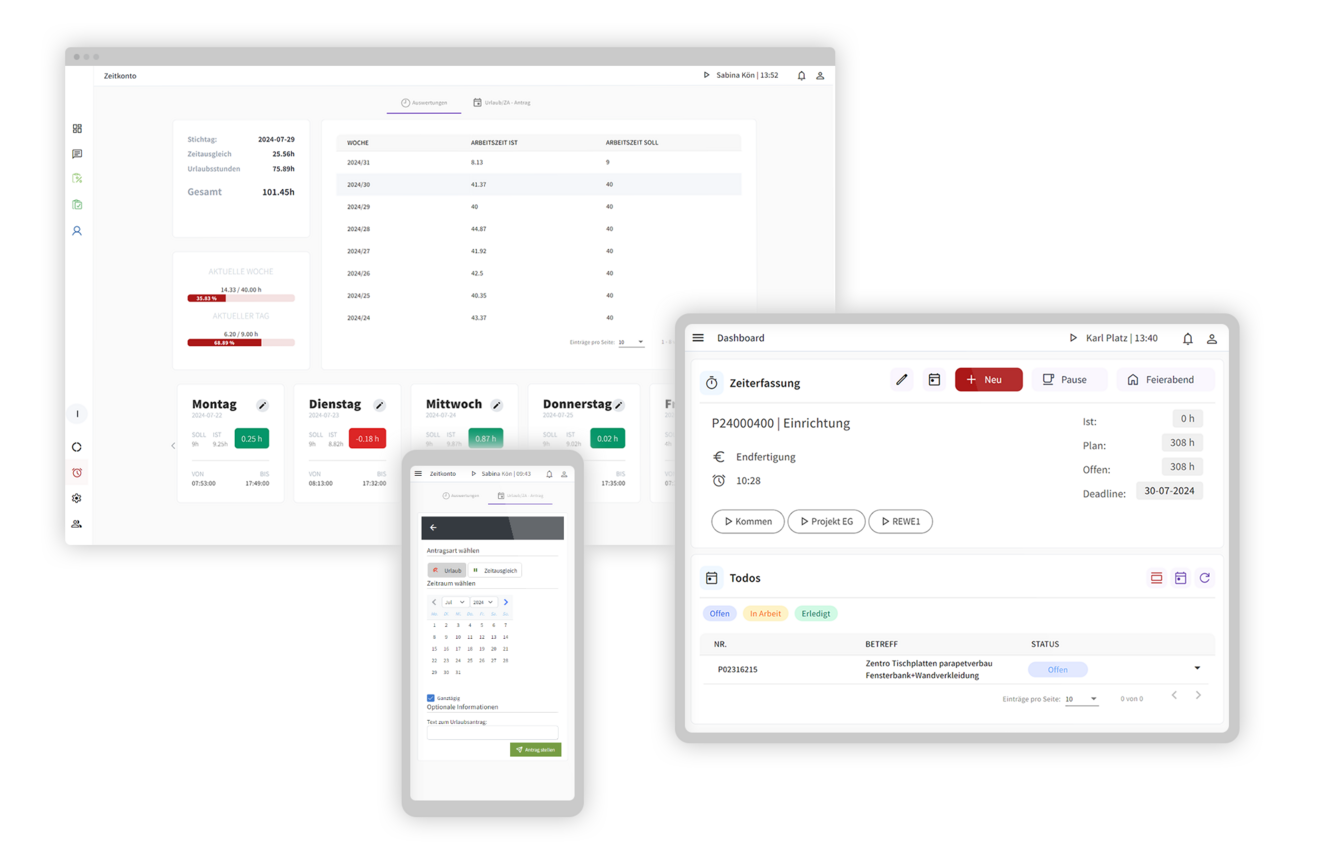

Use task management and time recording for your team in addition to the planning board via resource planning.

Success stories from our customers.

CARPENTRY

"With Zentro, we finally have all the information in one place. Everyone knows exactly what the status of an order is and what's coming up next. That makes our day-to-day work much easier."

Heiko Moldaschl

Junior manager and workshop manager

Schreinerei Moldaschl

Patrick Fleig

Technical Managing Director

Schreinerei Moosmann

BUILDING and FURNITURE CARPENTERS

"Everything works at least as promised and better than we thought it would."

Franz Hackl sen.

Managing Director

Tischlerei Hackl

CARPENTRY

"The biggest advantage of Zentro for us is that all processes are mapped in one interface. This creates transparency and traceability of orders. I chose Zentro because I think it's the best programme on the market."

Rüdiger Huschle

Managing Director

Schreinerei Huschle

PROPERTY DECORATOR

"We were looking for a long time for a solution that could meet our requirements in terms of innovation, flexibility, transparency and ease of use. Zentro Go was able to fulfil our individual requirements 100%."

Konrad Grömmer

Operations manager

Tischlerei Grömmer

Do you have any questions? We will be happy to advise you.

We look forward to your call at

!

Please write to us at

by e-mail!

Zentro GmbH

Grubbachstr. 71

4644 Grünau im Almtal

Austria