Papierlose Produktionsunterstützung durch ein Manufacturing Execution System (MES).

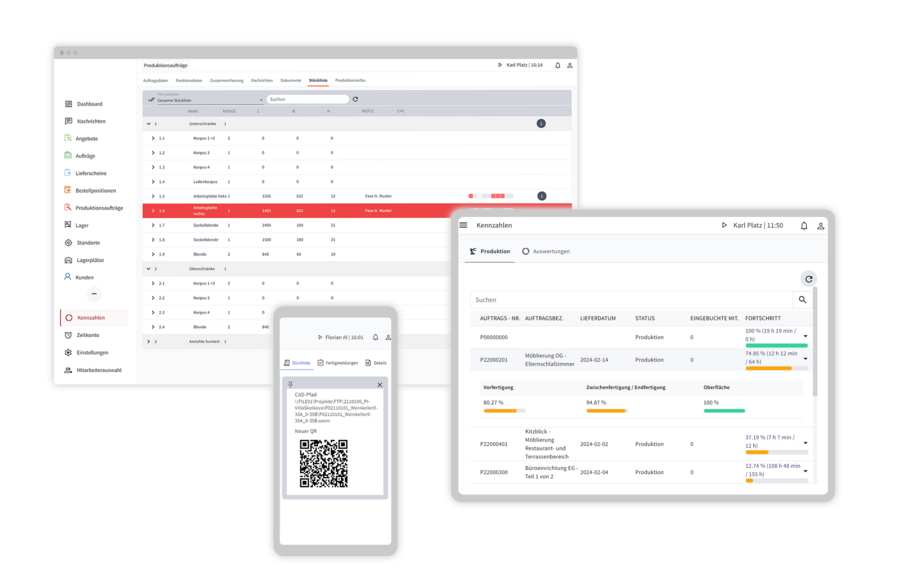

Setzen Sie Ihre Aufträge für Produktionsaufträge zusammen und übermitteln Sie alle Produktionsdaten direkt an Ihre Fertigungsanlagen. Rückmeldungen Ihrer Maschinen, Lagersysteme und Produktionsmitarbeiter können dann wiederum in Zentro importiert und für die Überwachung des Produktionsfortschritts genutzt werden.

Zentro stellt über CAM-Schnittstellen Produktionsdaten für Ihre Fertigungsanlagen bereit und nutzt Maschinendatenrückmeldungen (MDE) für die Materialbedarfsplanung und Fortschrittsüberwachung. Die Rückmeldungen durch Maschinendatenerfassung und Betriebsdatenerfassung werden nahtlos in Zentro integriert und genutzt. Damit Ihre Produktionsmitarbeiter optimal bei ihrer Arbeit unterstützt werden können, stehen digitale Arbeitsvorgaben, die Möglichkeit zur Fertigmeldung und zum Hinterlegen von Notizen und Dokumenten zur Verfügung. Diese garantieren einen reibungslosen Ablauf und helfen Fehler zu minimieren.

Produktionsleitsystem – Fertigungsmanagement in Echtzeit.

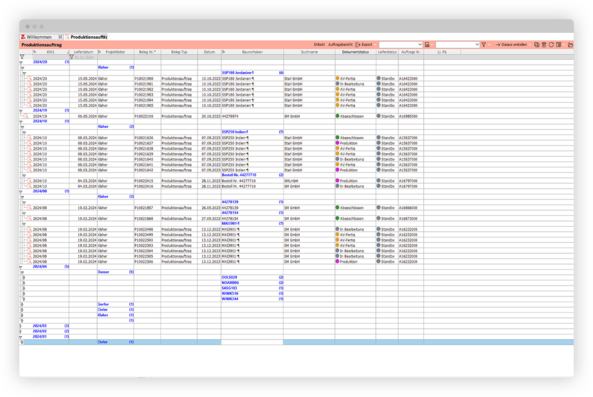

Planung und Abwicklung von Produktionschargen.

- Zusammenstellung von Produktionsaufträgen aus den erteilten Aufträgen und direkte Übermittlung an die Fertigungsanlagen.

- Anbindung von organisatorischen Objekten im Zusammenhang mit der Leistungsabrechnung (z. B. Gebäude, Räume, Anlagenteile).

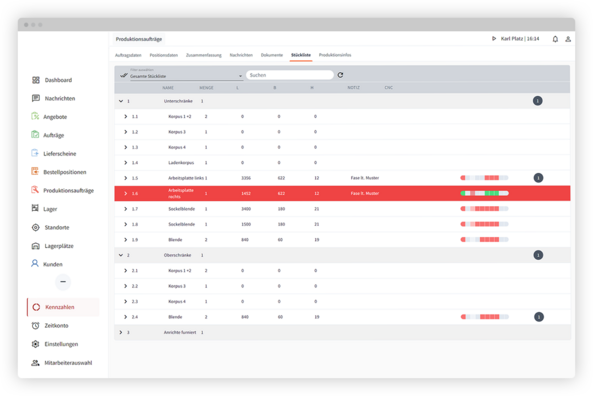

- Verwaltung von Produktionsstücklisten.

- Chargenplanung, sowohl auftragszerteilend als auch auftragsübergreifend: Zerteilung oder Zusammenfassung von Aufträgen zu Produktionslosen.

Manufacturing Execution System (MES) mit Integration in den Unternehmensprozess.

- Erstellung von produktionsauftragsbezogenen Bestellungen mit Querverweis zum Ursprungsauftrag.

- Prozessautomatisierung durch Maschinenschnittstellen, Betriebsdatenerfassung (BDE), Maschinendatenerfassung (MDE) und Personaldatenerfassung wird möglich.

- Verknüpfung mit der Zentro Kapazitätsplanung und Zeiterfassung.

- Automatisierte Zuweisung von Arbeitszeit und Materialkosten zu Produktionsaufträgen.

- Nachkalkulation auf Produktionsauftragsebene oder Kundenauftragsebene.

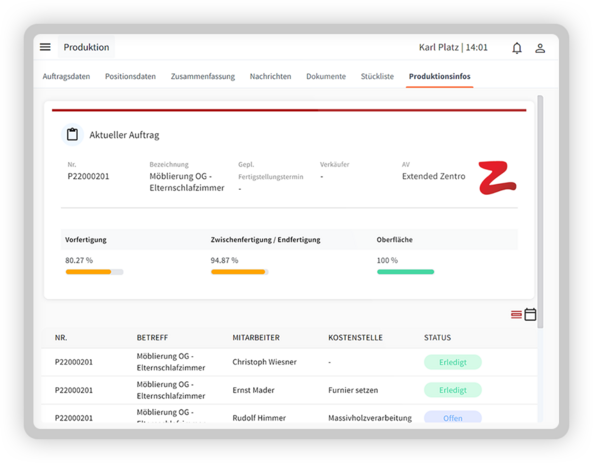

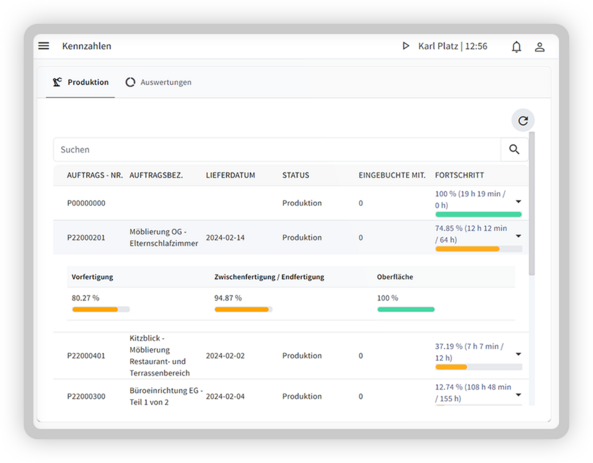

Produktionsmonitoring, Einzelteilverfolgung und Fertigmeldung - Ganzheitliche Leistungserfassung für maximale Planbarkeit: Übersicht und Lenkungsmechanismus.

Produktionsüberwachung: das mobile Monitoring.

- Alle Projekte übersichtlich auf einen Screen, auch via Tablet und Smartphone.

- Digitale Produktionsfortschrittsüberwachung und visualisierte Fertigstellungsgrade.

- Entscheidungsgrundlage zur Verbesserung Ihrer Fertigungsprozesse.

- Mehr Feedback und Planungssicherheit mit weniger Aufwand.

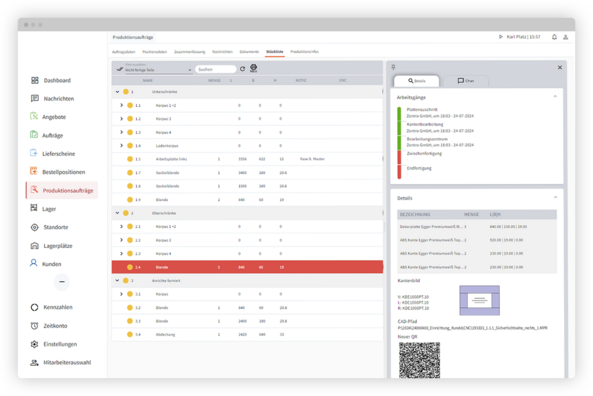

Detailinfos am

Produktionsterminal und Fertigmeldung:

- Anzeige von Materialverfügbarkeit bei Zukaufteilen.

- Teile basierte Statusinformation zu den durchlaufenen Arbeitsschritten einer Komponente.

- Kostenstellen basierte Vorgabezeitberechnung als Richtschnur für die Bearbeitungsdauer in der Produktion.

- Fortschrittsüberwachung und Fertigmeldung auf Produkt-, Gruppen- oder Einzelteilebene.

Durch die digitale Fertigmeldung weiß die Produktionsleitung genau über den Produktionsfortschritt Bescheid und kann entsprechend steuern.

Einzelteilverfolgung:

Produktionsfeedback auf Teilebasis.

Zu jeder Zeit genau über den Produktionsfortschritt Bescheid zu wissen, und das bei Losgröße 1, minimiert die Unsicherheit in der Planung und verschafft Spielraum in der Projektabwicklung und Kundenkommunikation.

- Mit der Einzelteilverfolgung geht nichts mehr im hektischen Arbeitsalltag unter.

- Rückmeldungen erfolgen strukturiert als teile basiertes Produktionsfeedback.

- Auf Probleme kann zeitnah reagiert werden.

- Fehlteile ohne Verzögerung nachproduziert werden.

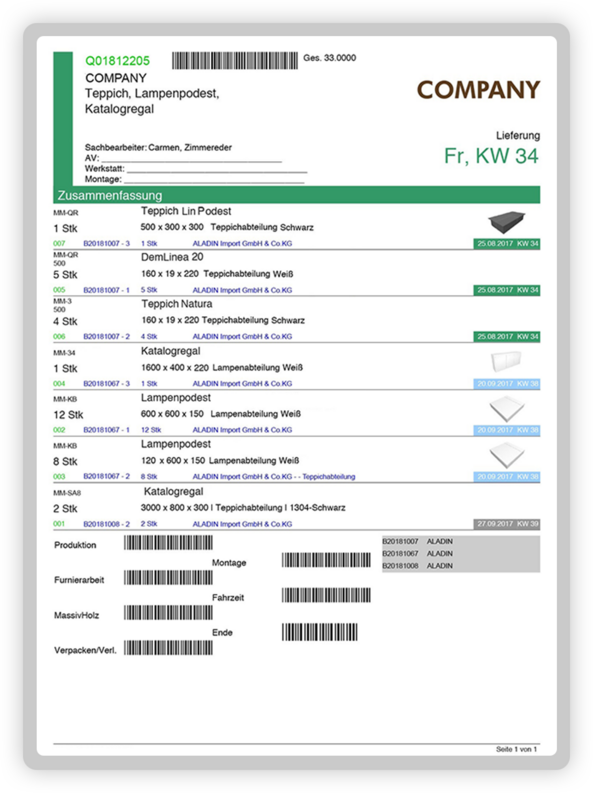

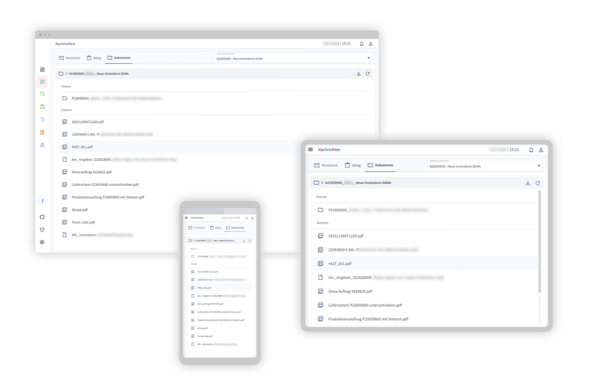

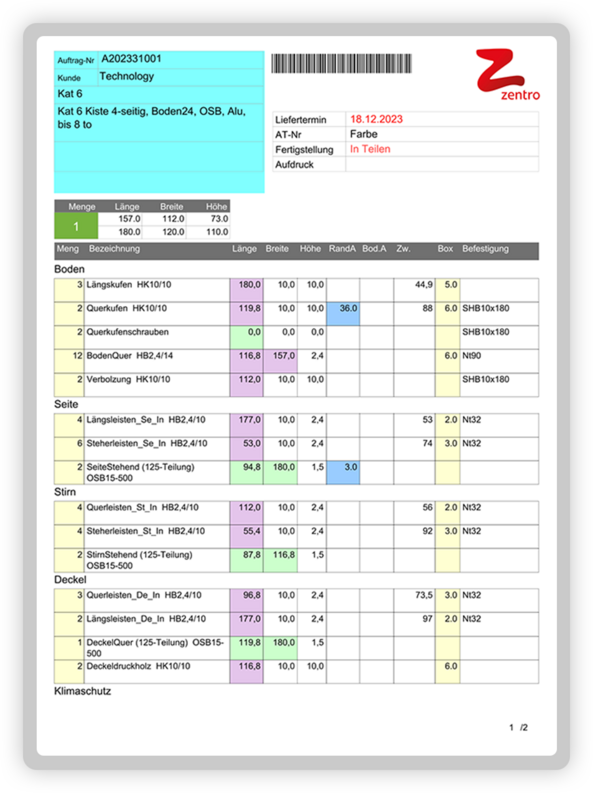

Digitale Dokumente - Produktion ohne Laufzettel in Papierform.

Digitale Fertigungsdokumente: Ausdrucken war gestern!

Werden Pläne geändert, werden die damit verbundenen Stücklisten und digitalen Laufzettel automatisch aktualisiert und stehen in Echtzeit für die Mitarbeiter in der Fertigung zur Verfügung:

- Das Ausdrucken von Dokumenten wird überflüssig.

- Aktuelle digitale Stücklisten und Zusatzinformationen statt veralteter Papiere.

- Mobile Dokumente ebnen den Weg zur papierlosen Fertigung (Paperless Factory).

Transparenz und Effizienz für alle Mitarbeitenden - keine offenen Fragen.

Jeder Projektbeteiligte soll Zugriff auf die Dokumente haben, die er für seine Arbeit braucht - und zwar in der aktuellsten Version:

- Stücklisten, Plandaten, Fotos, ergänzende Fertigungs- und Montageinfos, u. v. m. digital zum Projekt verfügbar.

- Unterlagen sind auch kurzfristig nachreichbar.

- Berechtigungssystematik regelt den Zugriff, damit jeder das sieht, was er sehen darf.

- Aufruf via Terminal in der Produktion oder unterwegs übers Tablet oder Smartphone.

Listen und pdf-Dokumente: Zum Versenden und Mitnehmen!

Fertigungsdokumente können individuell auf Ihre Bedürfnisse abgestimmt werden:

- Fertigungspapiere: mit Artikelbildern und farblicher Kennung nach Kalenderwoche.

- Barcodes und QR-Codes: Praktisch zum Scannen von Kostenstellen, Aufträgen oder Artikeln.

- Werkstattauftragspapiere, Laufzettel, Packzettel und Produktionsstückliste in A4/pdf-Format

- …

Die papierlose Fertigung ermöglicht rasche und fehlerfreie Änderungsprozesse und gibt Produktionsfeedback in Echtzeit.

Unsere Produktionssoftware ist als Zusatzmodul zu unseren ERP-Varianten erhältlich

ERP Light | ERP Kompakt | ERP Extended |

|---|

| Produktionsmanagement | |||

| Chargenplanung: auftragszerteilend und auftragsübergreifend | Nein | Ja | Ja |

| Aufteilung von Projekten in Produktionslose/Arbeitspakete | Nein | Ja | Ja |

| Automatisierte Aufteilung nach Funktions- oder Positionshierarchie | Nein | Ja | Ja |

| Verwaltung von Halbfertigprodukten | Nein | Nein | Ja |

| Auflösung von Produktionsstücklisten | Nein | Ja | Ja |

| Materialbedarfsermittlung und Auslösung von Fertigungsaufträgen | Nein | Ja | Ja |

| Verknüpfung zu Projekt und Objektelementen (z.B. Gebäude, Raum, ...) | Nein | Nein | Ja |

| Organisationselement von internen Arbeitspaketen | Nein | Ja | Ja |

| Möglichkeit zur Auftragsübergreifenden Positionszusammenfassung | Nein | Ja | Ja |

| Möglichkeit zur Auftragsübergreifenden Positionszusammenfassung | Nein | Ja | Ja |

| Produktionslos relevante Kostenerfassung und Nachkalkulation | Nein | Ja | Ja |

| Arbeitspaket basierte Materialreservierung | Nein | Ja | Ja |

| Produktionsvorschlag (anhand des verfügbaren Bestandes) | Nein | Ja | Ja |

| Druckmöglichkeit von Arbeitspapieren und Etikettierung | Nein | Ja | Ja |

| Baugruppenstatus und -fertigmeldung | Nein | Ja | Ja |

| Fertigungslog und QM-Daten | Nein | Ja | Ja |

| Dokumentenablage und Verlinkung zu Datenblättern | Nein | Ja | Ja |

| Seriennummerngenerierung und Etikettierung | Nein | Ja | Ja |

| Produktionsaufträge: interne Aufgabenverwaltung zu Arbeitspaketen/Produktionslosen | Nein | Ja | Ja |

| Fertigungsdokumente: Werkstattauftragspapiere, Laufzettel, Packzettel und Produktionsstückliste in A4/pdf-Format | Nein | Ja | Ja |

| Barcodes und QR-Codes: Scannen von Kostenstellen, Aufträgen oder Artikeln | Nein | Ja | Ja |

| Schnittstellen zu Fertigungsanlagen | Nein | Ja | Ja |

| Teilebasierte Produktionssteuerung | |||

| Digitale Produktionsstückliste | Nein | Nein | Ja |

| Eindeutige Teile-ID | Nein | Nein | Ja |

| Status/Fertigmeldung je Arbeitsgang und Einzelteil | Nein | Nein | Ja |

| Definition von Liefereinheiten und Monitoring der Fertigstellungsgrade auf Teileebene | Nein | Nein | Ja |

| Definition von Packstücken und Containerzuordnung | Nein | Nein | Ja |

| Teilebezogene Produktionszeiten | Nein | Nein | Ja |

| Teilbezogene Hinweis/Chatmöglichkeit mit konkreter Typisierungs- und Zuständigkeitsregelung | Nein | Nein | Ja |

| Fertigungs- und Qualitätsdokumentaion je Teil/Baugruppe | Nein | Nein | Ja |

| Gleichteilerkennung zur vereinfachten Berechnung von Arbeitszeiten | Nein | Nein | Ja |

| Plan/Dokumentenverwaltung zu Baugruppen oder Einzelteilen | Nein | Nein | Ja |

| Materialbezogene Produktionslose | Nein | Nein | Ja |

| Alternative Fertigungsrouten | Nein | Nein | Ja |

Profitieren Sie von Produktionsschnittstellen:

- Export von Produktionsstücklisten für Ihr CAM-System

- Import von Maschinendatenrückmeldungen

- Abgleich mit automatisierten Lagersystemen

- Maschinendatenerfassung (MDE), z. B. von Produktionsmengen

- Betriebsdatenerfassung (BDE), wie Rückmeldung auftragsbezogener Arbeitsleistungen, Auftragsstatus

Fortschrittsrückmeldung für die Produktionsüberwachung

Sie benötigen weitere Informationen zu Automatisierungen und Schnittstellen?

Paperless Factory.

“Wir waren lange auf der Suche nach einer Lösung, die unsere Ansprüche hinsichtlich Innovation, Flexibilität, Transparenz und Einfachheit in der Bedienung abdecken kann. Zentro Go konnte unsere individuelle Anforderung zu 100 % erfüllen.”

Konrad Grömmer

Geschäftsführer, Tischlerei Grömmer

Success Storys unserer Kunden.

OBJEKTAUSSTATTER

“Wir waren lange auf der Suche nach Lösung, die unsere Ansprüche hinsichtlich Innovation, Flexibilität, Transparenz und Einfachheit in der Bedienung abdecken kann. Zentro Go konnte unsere individuelle Anforderung zu 100 % erfüllen.”

Konrad Grömmer

Betriebsleiter

Tischlerei Grömmer

SCHREINEREI

"Der größte Vorteil von Zentro ist für uns, dass alle Prozesse in einer Oberfläche abgebildet sind. Dadurch entsteht eine Transparenz und Nachvollziehbarkeit der Aufträge. Ich habe mich für Zentro entschieden, weil es für mich das beste Programm auf dem Markt ist."

Rüdiger Huschle

Geschäftsführer

Schreinerei Huschle

BAU- und MÖBELTISCHLER

"Es funktioniert alles mindestens so wie versprochen und besser, als wir es uns gedacht haben."

Franz Hackl sen.

Geschäftsführer

Tischlerei Hackl

Sie haben Fragen? Wir beraten Sie gerne.

Wir freuen uns über

Ihren Anruf!

Schreiben Sie uns gerne

per Mail!

Zentro GmbH

Grubbachstr. 71

4644 Grünau im Almtal

Österreich